History of Scarf

The scarf, a fashion accessory whose main function is to keep you warm, has a rich history and variations. As far back as ancient Rome, people have been using scarf-like fabrics to protect themselves, mainly to absorb sweat. This ancient “scarf” was called a “sudarium”. However, the history of the scarf does not stop at practicality. In the 17th century, the scarf became a symbol of status and power. In Croatia, soldiers wore well-decorated scarves to signify their military status. This custom was then introduced to the French court by King Louis XIV of France, further fueling its unending popularity. By the 20th century, scarf design and manufacturing techniques had developed significantly. Silk scarves, wool scarves, modern synthetic material scarves, and many more appeared. Brands such as Hermes and Burberry introduced iconic scarf designs, making them an important element of fashion. Today, whether it’s a warm wool scarf or a flowing silk scarf, scarves have become our everyday accessories. Moreover, scarves can be worn in a variety of ways, such as French knots, infinity loops, shawls, and so on, each of which showcases a unique personality and style. When you wear a warm scarf in the cold winter or a silk scarf flowing in the spring breeze, you are not only protecting yourself but also showing the world your fashion taste and personality. Remember, a scarf is not just a tool to keep you warm; it’s your fashion statement.

Fabric Science

Cashmere

Cashmere is grown in the outer skin layer of the goat, covered in a thin layer of fine wool at the root of the coarse hair of the goat. The autumn equinox grows against the wind and cold, and sunshine after the equinox sheds, according to the length of time of the light, naturally adapted to the climate, belongs to the rare special animal fibres.

Cashmere accounts for only 0.2% of the world’s total animal fibre production and is priced in grammes in trade for its excellent quality and properties. It is believed that cashmere is the “Gem of Fibre,” the “Queen of Fibre,” incomparable to all the textile raw materials available to mankind, and is therefore also known as “soft gold”.

Lambswool

Lambswool is a variety of wool derived from the fleece of sheep, typically those that are less than 12 months old. Its frequent application lies in the production of plush blankets and clothes due to its attributes of softness, warmth, durability, and silky-smooth texture. Lambswool possesses some of the most delicate fibres in the wool industry. The additional thermal insulation offered by lambswool ensures optimal warmth, while the fabric’s lightweight nature guarantees all-day comfort when worn. Lambswool garments are lightweight due to the delicate nature of the fibres and the superior density of the fabric compared to other types of wool yarns. Additionally, it possesses inherent elasticity, enabling it to maintain its form and withstand elongation.

Lambswool possesses a combination of qualities that render it very suitable for crafting lightweight sweaters that provide ample warmth during the autumn and winter seasons without excessive thickness or bulkiness.

Polyester

Polyester fibre is a synthetic fibre referred to as PET fibre. It belongs to a kind of polymer compound. The invention of polyester fibre dates back to the 1930s, and today it is one of the most dominant synthetic fibres. Polyester fibre has many advantages. Overall, polyester fibre is a very used synthetic fibre, which is widely used in fields such as textile and garment manufacturing and brings a lot of convenience and comfort to our daily lives.

- Good wrinkle resistance and good shape retention. Products made from polyester fibres do not wrinkle easily and retain their original shape.

- High strength and elastic recovery. Polyester fibres make woven fabrics strong and durable, and at the same time, they can be quickly restored to their original shape.

- It is resistant to abrasion and does not stick to lint. Polyester fibres are also resistant to abrasion and do not stick to lint, giving fabrics a neater look.

- Good abrasion resistance. Its abrasion resistance is second only to nylon and second among synthetic fibres, better than other natural and synthetic fibres.

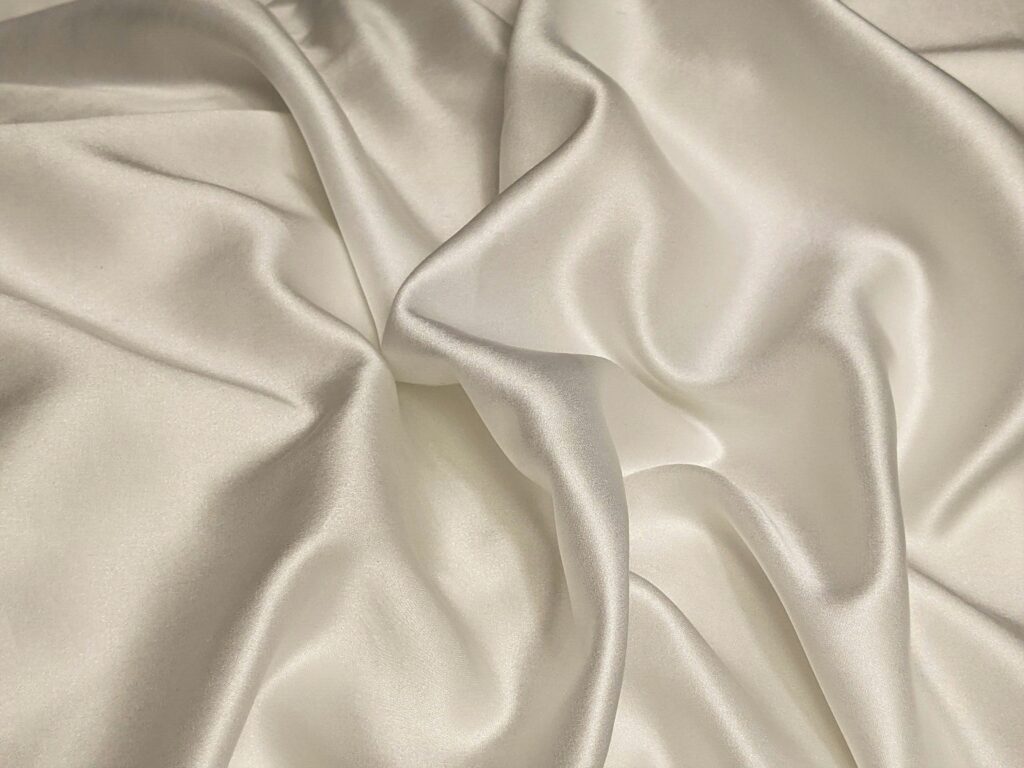

Silk

The process of silk manufacture commences with the cultivation of silkworms. Silkworm eggs are meticulously cultivated until they emerge as larvae. After emerging from their eggs, silkworms consume mulberry leaves as their primary source of nourishment. They devour them with great eagerness and experience quick growth. During this duration, which spans around one month, they undergo multiple moulting processes. Following their final moult, they commence the process of constructing their cocoons.

Subsequently, silkworms excrete a viscous substance known as sericin, which solidifies upon exposure to air, resulting in the formation of a safeguarding cocoon. The cocoon functions as a protective structure for the silkworm and is the origin of silk filaments. Prior to the metamorphosis of silkworms into moths, the cocoons are meticulously collected. In order to acquire lengthy and uninterrupted silk filaments, it is customary to subject the cocoons to boiling, a process that results in the demise of the silkworms enclosed within.

After the cocoons are gathered, the procedure of unwinding the silk commences. The cocoons are submerged in heated water to soften the sericin and allow the extraction of the silk fibres. Multiple cocoons are meticulously unravelled and merged to create a solitary silk filament.

After the extraction process, the silk strands undergo twisting to create the final silk thread. The thread is coloured and processed in preparation for the weaving process. Silk fabric is formed through the process of interlacing threads on a loom, which yields a range of silk textiles including silk satin, silk gauze, and silk brocade.